The Use of Aluminum in the Food Packaging

In 1911, the Tobler factory in Switzerland, which produced Toblerone chocolate, was the first industry to use aluminum foil for food packaging.

Today, this is one of the most widely used materials for food packaging, due to its cost-effectiveness, the ability to be fully recyclable and many other applications.

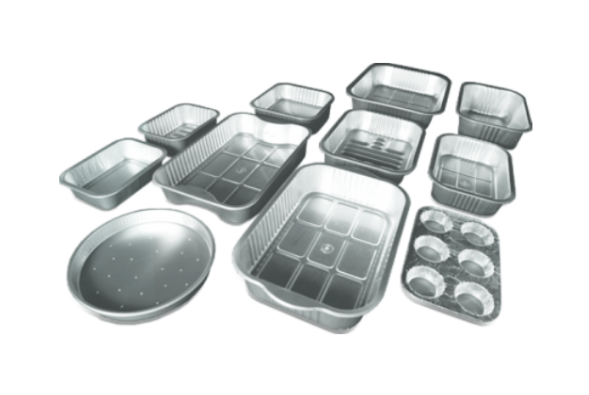

Commonly, the aluminum used in food packaging is mainly found in catering packaging, sachets, bags, bottlenecks, capsule sheets, labels and seals.

Main features of aluminum packaging

Sunlight negatively affects many foods, which damages their appearance and worsens their taste; but aluminum foil solves this problem, in addition to its ability to store food for long periods, thus also avoiding contact with germs and bacteria.

This container provides a barrier to light, gases, oil, fats, volatile compounds and steam. It is resistant to temperature, has good heat conductivity, resistance and durability, is flexible and has ease to shape it; it does not weigh, it is recyclable and has a decorative potential for its glossy or matte surface.

Apart from all these properties, aluminum is non-toxic and is compatible with food; but is it dangerous for our health?

Can the aluminum in the packaging get into the food and affect the health of the consumer?

Aluminum as an element can be found in food for several reasons, but the most common is the one that occurs naturally (it is the most abundant metal in the Earth’s crust) migrating to food through aluminum cookware or packaging.

The Food Standards Agency (FSA) regularly measures the amount of aluminum in our diet. They have found that the levels of aluminum consumed in food are within the safety standards of World Health Organizations. FSA food survey on aluminium and other elements in packaged food (link is external).

Studies have shown that packaging in aluminum containers increased these metal levels in food by only a minimal amount, leading researchers to conclude that the use of aluminum foil for food packaging is safe for its consumers. The manufacture of aluminum containers must comply with the standards established by European Regulation 1935/2004, and must not modify the nature, consistency or quality of the food.

The aluminum food packaging market

The food and beverage industry is the largest end user of aluminum foil packaging and held more than 28% of the total market share in 2015 in the global market.

Approximately 7 billion aluminum containers are produced annually. We could say that about 220 packages are produced every second. The packaging of pet food, tuna, coffee and soups alone produces 13 billion packages that could be made from aluminum foil.

Thus, because it is a practical, durable and attractive material, aluminum foil meets the requirements that the food industry requires for its packaging and is the best option for your product.

Aluminum foil: the favorite in the food industry

Often, when talking about food packaging, aluminum foil is one of the most chosen options, since the contact between the foil and the food or beverages in question does not cause any reaction and, instead, brings multiple benefits for their conservation, as it functions as a barrier against oxygen, moisture and other environmental factors that can lead to their decomposition.

In this way, the useful life of the product is extended and the safety of the final consumer is guaranteed.

Attractive image

Once we have dealt with one of the most important points regarding food packaging, such as preservation, let’s talk about another equally relevant in marketing terms: the image.

Aluminum is an attractive material by itself that, applied to packaging, transfers those same characteristics to them: brightness and high decorative potential. It is also possible to adapt it to the needs of a brand through printing; for example, so that the product packaging contains its logo.

Thus, the food product will be attractive to the consumer at the time of the purchase choice.

Flexible material

In addition to the above, aluminum foil is a flexible material that adapts to the packaging needs of almost any product, since it folds and covers it perfectly, respecting its shape, which is extremely attractive for the industry.

The Recycle of Aluminum Containers

Disposable aluminum trays are one of the most frequent packaging products in any hospitality and food sales business, whether in bulk or retail. That is why, from Envaseonline we have thought it interesting to address its recycling, even more considering how important this issue is currently.

Which container do I throw the single-use aluminum trays of my business into?

Nicholl Food Packaging, a company located at Cannock, Staffordshire, the United Kingdom, suggests that disposable aluminum trays are one of the essentials for takeaway food businesses. Thanks to their packaging characteristics, they allow food to be preserved optimally during the journey from the premises to the customer’s home.

This makes the use of these aluminum containers very frequent in businesses and restaurants with delivery service. For this reason, users should know the correct ways to dispose of these containers, throw them away and recycle them effectively.

First of all, the user should know that these aluminum containers should be thrown into the yellow container. In addition, the so-called “ball theory” must be applied. In this regard, aluminum containers are divided into three types, according to their ability to turn into a ball:

- Rigid aluminum containers: cans for drinks and soft drinks.

- Semi-rigid aluminum products: trays of pre-cooked foods, tubs of custard or yoghurts.

- Flexible aluminum packaging: aluminum films for packaging food or yogurt lids.

The single-use aluminum trays are part of the category aluminum semi-rigid containers. These are malleable enough to turn them into a ball, which the user will have to form before putting them in the bag or trash can. This way they will be ready for recycling.